ABOUT US

Time Refines Excellence

The Universe Captured in Copper

TONGSHIFU CULTURAL AND CREATIVE GROUP

133,000㎡

Production Complex

160,000㎡

Workshops

1,500+

Artisans

Tongshifu Brand Story

Where Art Meets Legend

At Tongshifu, we believe that true art is not just seen — it’s felt. It tells a story, carries tradition, and stands the test of time. Our journey began with a simple question: How can we bring legendary characters to life in a way that honors both craftsmanship and culture?

The answer lies in our name — Tongshifu.

We are artists, sculptors, and storytellers who transform molten metal into timeless masterpieces using the ancient lost wax casting technique. Every piece in our collection is handcrafted with precision, from the first wax carving to the final patina finish. Each sculpture captures not only the form of a character but also its soul — whether it’s a heroic Transformer, a mythical Chinese guardian, or a beloved pop culture icon.

Our mission is to create more than just collectibles — we craft legacies in copper alloy, pieces that can be passed down through generations. With every detail meticulously refined and every finish carefully applied, we strive to elevate metalwork into high art.

Today, Tongshifu is known for blending cutting-edge design with centuries-old techniques, offering collectors and fans alike a new way to experience their favorite legends — not as fleeting images on screen, but as enduring sculptures of strength, beauty, and meaning.

The Art of Lost Wax Casting: Transforming Imagination into Reality

The journey from design to art

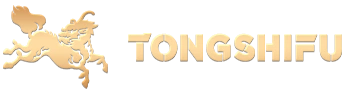

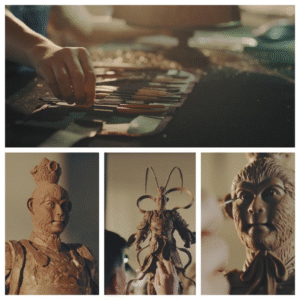

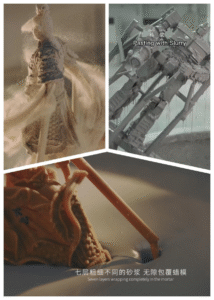

Step 1: Wax Sculpting

“From Vision to Form – The First Stroke of Artistry”

It all begins with a vision. Master sculptors bring Transformer designs to life by hand-carving every detail in wax — from the smallest gear to the boldest armor plate. This stage is where creativity meets craftsmanship, laying the foundation for an unforgettable metal masterpiece.

“Precision in Every Curve – The First Drop of Wax”

Every masterpiece begins with a single drop. Molten wax is carefully injected into a precision-engineered mold, capturing every mechanical detail — from the sharp angles of a Transformer’s armor to the subtle articulation of its joints. This is where imagination meets craftsmanship.

Step 2: Wax filling

Step 3: Repair wax

“Handcrafted Perfection – Refining the Vision”

No two pieces are ever exactly alike. Skilled artisans inspect and refine each wax model by hand, smoothing imperfections, adjusting proportions, and ensuring that every line tells the story of a true Transformer legend.

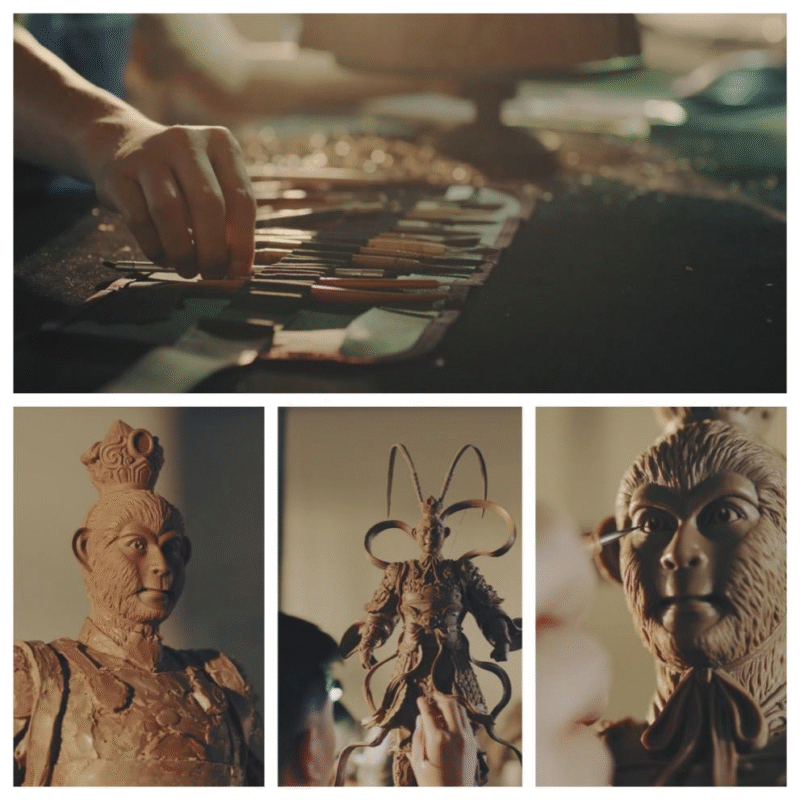

“Building the Future – One Layer at a Time”

A fine ceramic slurry is applied by hand over the wax sculpture, layer by layer, forming the future shell that will protect the design through fire and metal. Each dip brings us one step closer to permanence.

Step 4: Slurry Coating

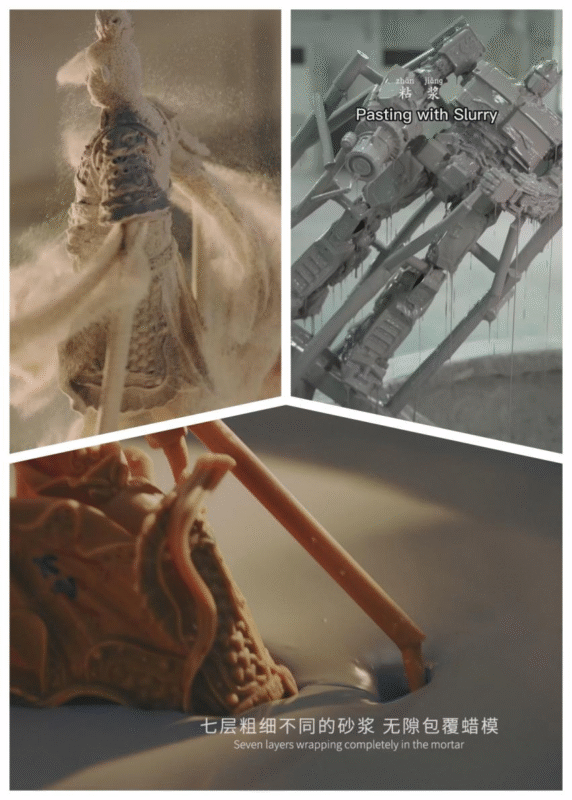

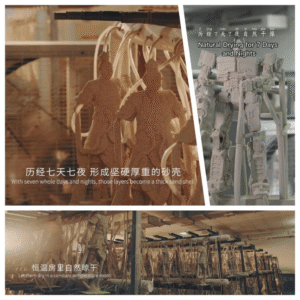

Step 5: Natural Drying

“Time as an Ingredient – Letting Nature Take Its Course”

The coated sculpture rests under controlled conditions, allowing the ceramic layers to harden naturally. This slow drying ensures structural integrity — a quiet but essential part of the journey.

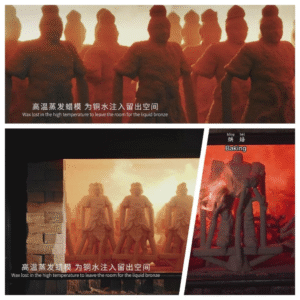

“From Wax to Hollow Promise – The Fire Reveals All”

In the kiln’s heat, the wax vanishes entirely, leaving behind a hollow ceramic shell — a ghost of the original form, now ready for its transformation into bronze.

Step 6: Baking

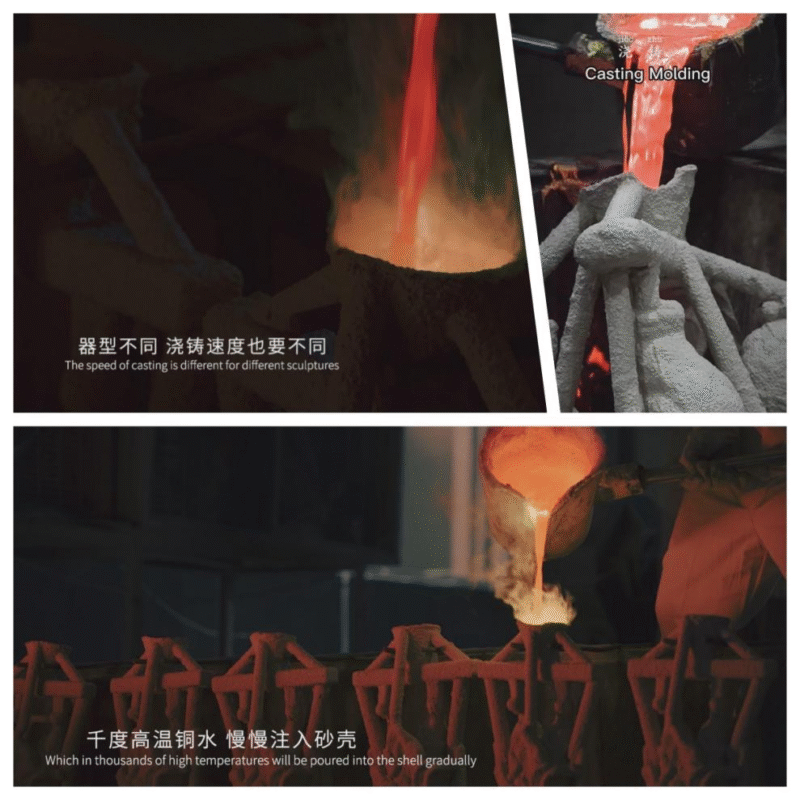

Step 7: Metal Pouring

“The Moment of Truth – Liquid Bronze Takes Shape”

Molten copper alloy, glowing white-hot, is poured into the ceramic shell. As it cools, the metal takes on every contour and detail of the original wax model — now reborn in solid form.

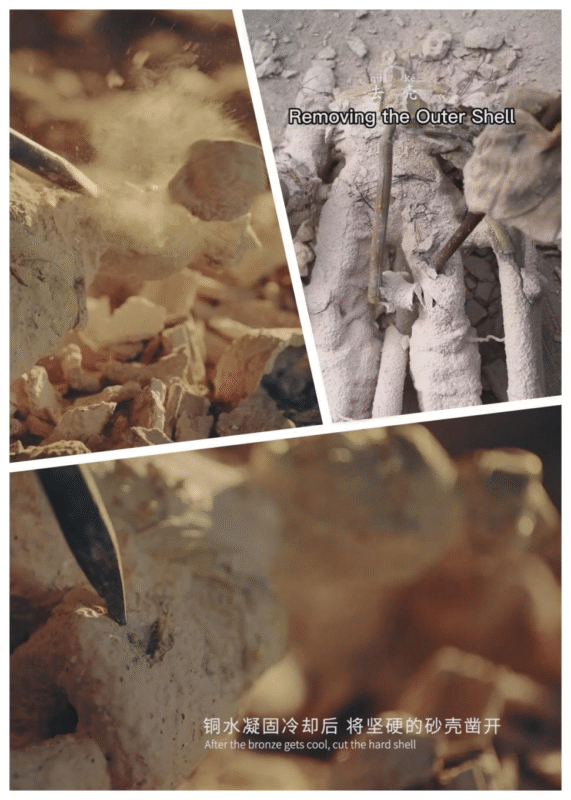

“Unveiling the Core – A Sculpture Emerges”

With careful hands, the ceramic shell is broken away, revealing the raw bronze sculpture inside. It’s the first glimpse of the final artwork — powerful, unfinished, and full of promise.

Step 8: Shell Removal

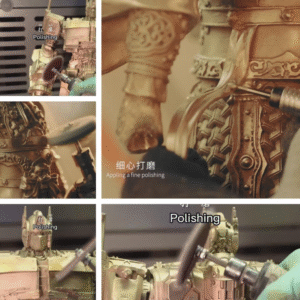

Step 9: Fine grinding

“Polishing the Legend – From Rough to Radiant”

Each edge, surface, and joint is polished by hand, bringing out the brilliance of the metal. This is where the sculpture transforms from rough casting to refined art — a true tribute to Transformers’ legacy.

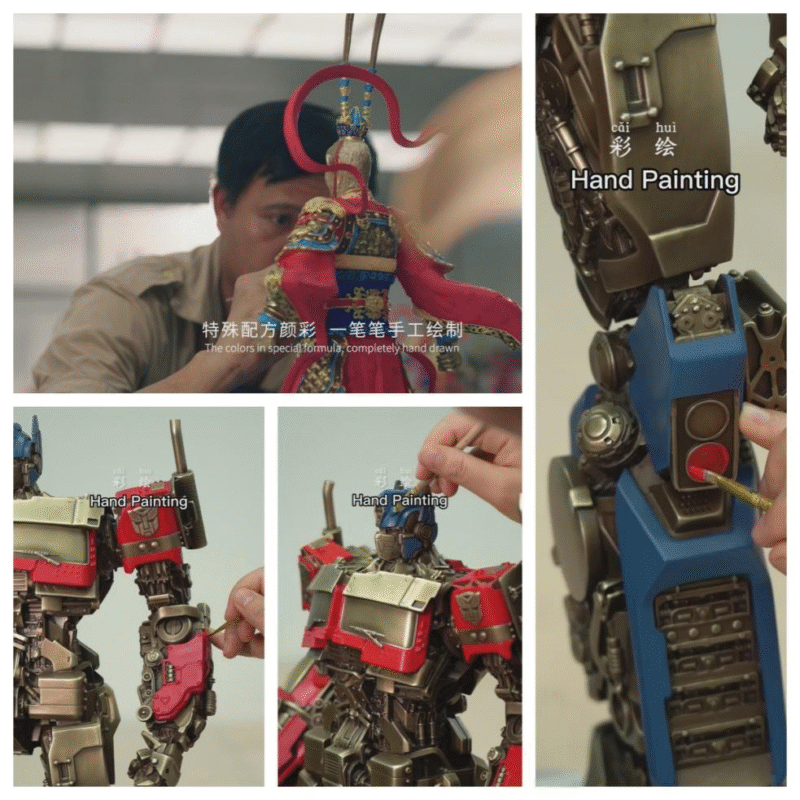

“Bringing Life to Metal – Color, Depth, and Character”

Using traditional patina techniques, artists apply color and texture by hand, enhancing depth and realism. The result? A timeless piece that captures both the strength and soul of the Transformer spirit.

Step 10: Hand-drawn

Own a collection of this incredible craftsmanship – a true fusion of art, engineering and passion.

[Shop the Collection Now] or [Explore Our Story]

The Art of Lost Wax Casting: Transforming Imagination into Reality

The journey from design to art

Step 1: Wax Sculpting

“From Vision to Form – The First Stroke of Artistry”

It all begins with a vision. Master sculptors bring Transformer designs to life by hand-carving every detail in wax — from the smallest gear to the boldest armor plate. This stage is where creativity meets craftsmanship, laying the foundation for an unforgettable metal masterpiece.

Step 2: Wax filling

“Precision in Every Curve – The First Drop of Wax”

Every masterpiece begins with a single drop. Molten wax is carefully injected into a precision-engineered mold, capturing every mechanical detail — from the sharp angles of a Transformer’s armor to the subtle articulation of its joints. This is where imagination meets craftsmanship.

Step 3: Repair wax

“Handcrafted Perfection – Refining the Vision”

No two pieces are ever exactly alike. Skilled artisans inspect and refine each wax model by hand, smoothing imperfections, adjusting proportions, and ensuring that every line tells the story of a true Transformer legend.

Step 4: Slurry Coating

“Building the Future – One Layer at a Time”

A fine ceramic slurry is applied by hand over the wax sculpture, layer by layer, forming the future shell that will protect the design through fire and metal. Each dip brings us one step closer to permanence.

Step 5: Natural Drying

“Time as an Ingredient – Letting Nature Take Its Course”

The coated sculpture rests under controlled conditions, allowing the ceramic layers to harden naturally. This slow drying ensures structural integrity — a quiet but essential part of the journey.

Step 6: Baking

“From Wax to Hollow Promise – The Fire Reveals All”

In the kiln’s heat, the wax vanishes entirely, leaving behind a hollow ceramic shell — a ghost of the original form, now ready for its transformation into bronze.

Step 7: Metal Pouring

“The Moment of Truth – Liquid Bronze Takes Shape”

Molten copper alloy, glowing white-hot, is poured into the ceramic shell. As it cools, the metal takes on every contour and detail of the original wax model — now reborn in solid form.

Step 8: Shell Removal

“Unveiling the Core – A Sculpture Emerges”

With careful hands, the ceramic shell is broken away, revealing the raw bronze sculpture inside. It’s the first glimpse of the final artwork — powerful, unfinished, and full of promise.

Step 9: Fine grinding

“Polishing the Legend – From Rough to Radiant”

Each edge, surface, and joint is polished by hand, bringing out the brilliance of the metal. This is where the sculpture transforms from rough casting to refined art — a true tribute to Transformers’ legacy.

Step 10: Hand-drawn

“Bringing Life to Metal – Color, Depth, and Character”

Using traditional patina techniques, artists apply color and texture by hand, enhancing depth and realism. The result? A timeless piece that captures both the strength and soul of the Transformer spirit.

Own a collection of this incredible craftsmanship – a true fusion of art, engineering and passion.

[Shop the Collection Now] or [Explore Our Story]

We work through every aspect at the planning

Co-branding

Tongshifu's craftsmen bring the classic characters, scenes and props in the film IP to life in the form of copper art with their exquisite skills and unlimited creativity. Each work has been carefully designed and repeatedly polished, and strives to perfectly restore the essence of film and television works, while giving it unique artistic value and cultural connotation.

Cultural relics revitalization

Tongshifu's craftsmen, with their exquisite skills and unlimited creativity, bring the museum's collection of cultural relics to life in the form of copper art. We use the combination of traditional craft and modern technology to carefully reproduce the details of cultural relics, and strive to perfectly restore the historical style of cultural relics, while giving them new artistic life.

Create quality products

Tongshifu has a wide range of original works, covering home accessories, art, collectibles and other fields. According to the needs of different users, we design different styles and different functions of copper art works to meet people's diversified aesthetic and practical needs.

Business Partner

More than 10,000+ users have chosen us